Mesin Pengemas Busa Vertikal Isi Segel Gerak Kontinu Kecepatan Tinggi

Mesin Pengemas Busa Vertikal Isi Segel Gerak Kontinu Kecepatan Tinggi

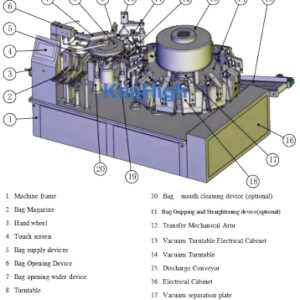

The Vertical Form Fill Seal (VFFS) Continuous Motion High-Speed Packing Machine is designed for efficient, high-speed packaging of granular products such as chips, salty beans, nuts, snacks, flavored ice balls.. This machine is integral to various industries due to its versatility, reliability, and ability to produce up to 150 bags per minute.

Main Performance and Structural Features

- High-Speed Operation: Capable of producing up to 150 bags per minute, ideal for industries requiring high throughput.

- Advanced Control System: Features an imported PLC full computer control system with a user-friendly human-machine interface (HMI), allowing for easy operation via a large touch screen display.

- Precision Mechanism: The packaging film running system is driven by a servo motor, ensuring accurate positioning and excellent performance.

- Enhanced Reliability: The overall reliability and intelligence of the machine are maximized, contributing to consistent performance.

- Comprehensive Automation: Equipped with a metering device that automates the entire process, including material feeding, bag making, filling, date printing, air filling (exhaust), counting, and product transportation.

Packaging Material Specifications

- Film Rolls: Suitable for rolls with an outer diameter of ≤320 mm and an inner diameter of ≤75 mm.

- Material Thickness: Composite packaging materials should be between 0.05 mm and 0.08 mm.

- Surface Requirements: The surface must be flat with no waviness. A 10 mm margin from the edge should remain unprinted, ensuring a pure background color that contrasts clearly with any printed elements.

Key Advantages

- Consistent Operation: The continuous motion mechanism minimizes the risk of product spillage and packaging defects, ensuring smooth operation.

- Penyegelan Presisi: Ensures perfect sealing of bags to prevent leakage and maintain product freshness.

- Customizable Options: Jingrui offers tailored VFFS machines to meet specific packaging demands, including both normal speed and continuous motion models.

Additional Features

- Full intelligent PLC control for enhanced operational efficiency.

- Servo motor-driven pulling belts and horizontal sealing mechanisms.

- Easy-to-change forming tubes and parts made of food-grade stainless steel.

- Smart control system with alarm detection and data logging capabilities.

- A robust and clean design with convenient back seal alignment.

- Self-aligning and vacuum-pulling belts for optimal performance.

- Options for various enhancements, including:

- Side gusseting assembly

- Pembilasan gas nitrogen

- Rahang penyegel poli

- Static eliminators

- Membentuk pipa knalpot

- Hole/handle punch

- Thermal transfer or laser printers

- Tear notches

- Conveyor options (take-away, indexing, slope type, Z-type)

- Hopper vibrators

Parameter Teknis

Bag length: 80-300 mm

Bag width: 60-200 mm

Maximum width of roll film: 420 mm

Packing Material: OPP/CPP, OPP/PE, PET/PE

Packing speed: 150 bags/min

Measuring range: 150 ml-1200 ml

Air Consumption: 065 MPa

Gas consumption: 0.3 meter cube per min

Power voltage: 220V (AC), 50 Hz

Dimensions: (L) 1080 mm * (W) 1300 mm * (H) 1400 mm

Approximate weight of machine: 540 kg

Pengingat yang baik

Harap berikan informasi berikut saat Anda mengirimkan pertanyaan. Berdasarkan pesan Anda, kami akan menyarankan solusi optimal untuk referensi Anda. Terima kasih.

- Dimensi tas

- Berat per tas

- Produk Anda

- Bentuk tas

- Bahan film